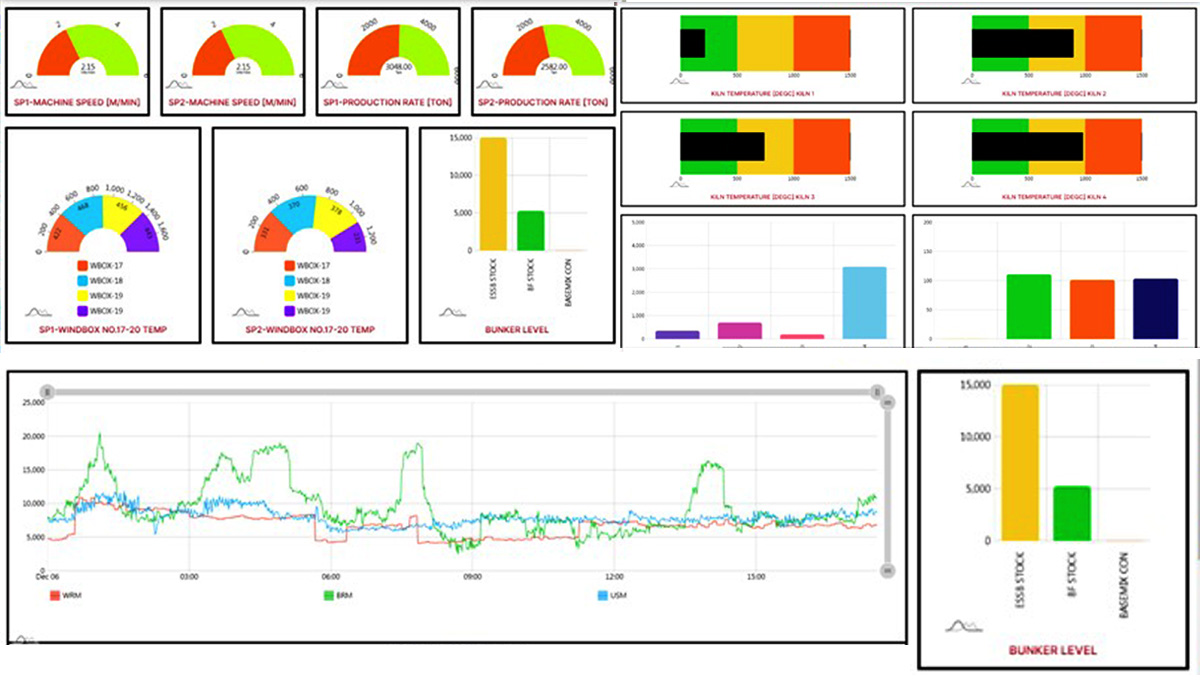

Implementation of UPV (Unified Plant View) of SAIL IISCO STEEL PLANT “Automate Production Process, Realtime Monitoring with Analysis Reporting System” of various department (Blast Furnace, Sinter Plant, Basic Oxygen Furnace, Continuous Costing Plant, Ladle Heating Furnace, Mills, Power and Blowing Station, Oxygen Plant, CBM, Coke Ovens , By Product Plant, Lime & Dolo Calcination Plant) and integration of different Plant in a single window that help to control all the plant effectively and efficiently by using of emerging technology like PLC, OPC, OPC client, Centralize Big DB Implementation(Info Cube , OLTP, & OLAP ), Digestor recovery and purgation of Email Server

Benefits for SAIL IISCO Steel Plant

- Improved Productivity

- Minimized downtime through predictive maintenance.

- Better resource allocation and process synchronization.

- Enhanced Quality

- Real-time monitoring ensures consistent product quality.

- Cost Efficiency

- Reduced operational costs through process optimization and energy savings.

- Better Safety and Environmental Performance

- Improved safety monitoring and reduced emissions.

- Streamlined Decision-Making

- Instant access to data facilitates quicker and more informed decisions.

Key features of UPV include:

- Real-time data visualization.

- Process optimization through analytics.

- Centralized monitoring of operations.

- Predictive maintenance capabilities.