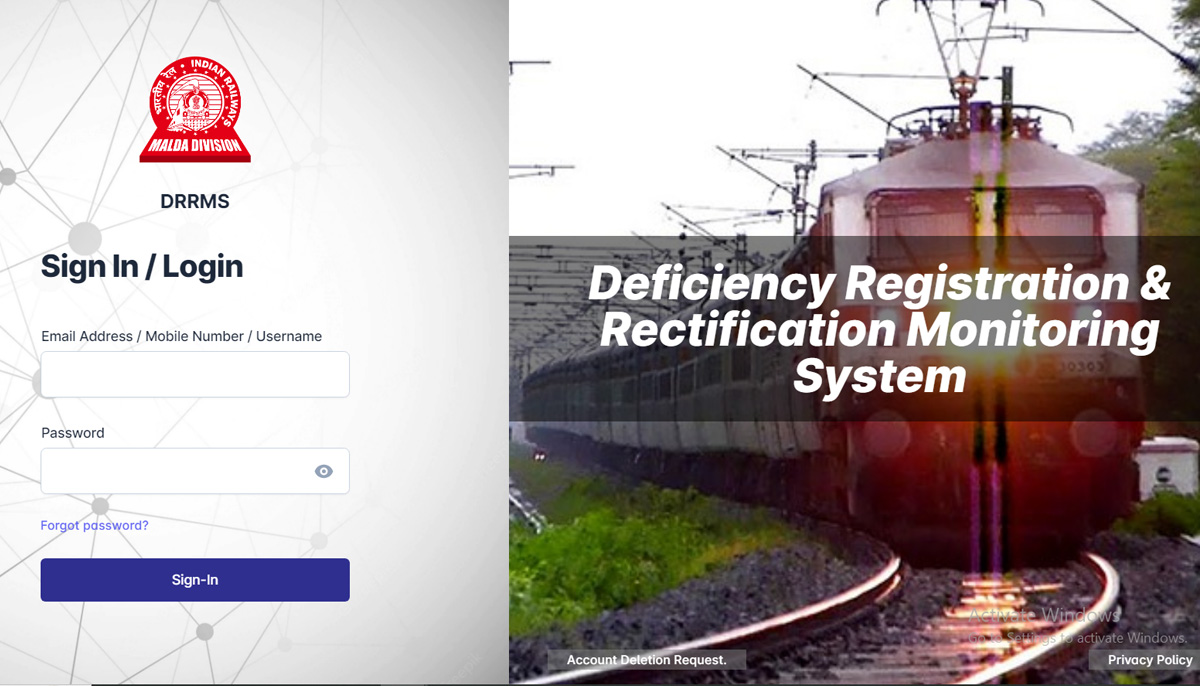

The Deficiency Registration & Rectification Monitoring System (DRRMS) is a framework designed to identify, register, and monitor deficiencies in passenger amenities, safety measures, and cleanliness across railway stations and trains. The system ensures systematic rectification of issues, improving the overall passenger experience and ensuring operational compliance with safety and quality standards.

Key Features of DRRMS

- Deficiency Identification and Registration

- Mechanism for reporting deficiencies in areas such as:

- Passenger Amenities: Waiting rooms, drinking water facilities, seating, lighting, escalators, and lifts.

- Safety: Signal malfunction, track issues, fire extinguishers, emergency exits.

- Cleanliness: Platform cleanliness, toilets, dustbins, and train interiors.

- Reports can be generated by:

- Railway staff during inspections.

- Passengers through designated complaint channels.

- Mechanism for reporting deficiencies in areas such as:

- Centralized Monitoring

- All registered deficiencies are logged into a centralized database for better tracking and analysis.

- Integrated with platforms like IROMS or other railway management systems.

- Prioritization and Categorization

- Issues are categorized based on severity and impact (e.g., critical safety issues vs. minor cleanliness complaints).

- Prioritized to ensure timely rectification of critical issues.

- Task Assignment

- Automatically assigns tasks to the concerned department or personnel responsible for addressing the deficiency.

- Includes timelines and reminders for resolution.

- Real-Time Tracking and Reporting

- Continuous tracking of the rectification process to ensure accountability.

- Generates status reports for senior management and regulatory oversight.

- Integration with Audit and Inspection Systems

- Supports routine audits and inspections by providing data on recurring issues and resolution timelines.

- Enables better resource allocation and long-term planning.

Benefits of DRRMS

- Enhanced Passenger Satisfaction

- Proactive identification and resolution of issues improve the quality of services provided to passengers.

- Builds trust and confidence in railway services.

- Improved Safety Standards

- Ensures critical safety deficiencies are addressed promptly, reducing the risk of accidents.

- Operational Efficiency

- Streamlines the process of deficiency reporting and rectification, reducing manual follow-ups.

- Helps identify trends and recurring issues for better preventive measures.

- Transparency and Accountability

- Centralized monitoring ensures that all issues are tracked until resolved.

- Promotes accountability among railway staff and contractors.

- Data-Driven Decision Making

- Historical data helps in analyzing common problem areas, optimizing resource allocation, and planning upgrades.

Workflow

- Deficiency Reported: A signal malfunction is identified by railway staff or a passenger.

- Issue Logged: Details are registered in the DRRMS, specifying location, type, and severity.

- Task Assigned: The system assigns the task to the signaling maintenance team with a defined deadline.

- Progress Monitoring: Updates are provided at each stage, including when the issue is fixed.

- Resolution Verified: Final inspection ensures the problem is resolved. The status is updated to "closed."

- Report Generated: A report is generated for management, showing resolution time and compliance.

By automating and streamlining the deficiency rectification process, DRRMS contributes significantly to Indian Railways' goal of improving service quality, safety, and operational efficiency.