Automation

Our automation solutions leverage advanced technology to perform tasks with minimal human intervention, enhancing efficiency, accuracy, and scalability. Softmeets streamlines workflows, reduces costs, and minimizes errors, all while enabling seamless 24/7 operations. By automating repetitive tasks, we empower organizations to allocate resources to strategic initiatives, enhance safety by managing hazardous processes, and ensure compliance through consistent and reliable execution.

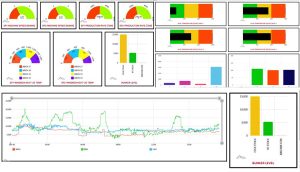

With real-time monitoring and predictive analytics, automation drives data-driven decision-making and operational agility, resulting in better productivity, customer satisfaction, and long-term sustainability.

Empowering Efficiency, Elevating Accuracy

Increased Efficiency

Faster Execution: Automation completes tasks faster than manual efforts, reducing process cycle times.

24/7 Operation: Automated systems can run continuously without breaks or downtime.

Streamlined Workflows: Reduces bottlenecks by automating sequential tasks.

Cost Savings

Reduced Labor Costs: Minimizes the need for repetitive manual work, allowing employees to focus on strategic tasks.

Lower Operational Costs: ptimizes resource usage, such as energy and materials, in industrial automation.

Error Reduction: Fewer errors mean lower costs associated with rework or waste.

Improved Accuracy

Minimized Human Errors: Automation eliminates mistakes caused by fatigue or oversight.

Consistent Quality: Ensures uniformity in task execution, enhancing product and service quality.

Enhanced Productivity

Scalability: Easily handles increased workloads without hiring additional staff.

Task Prioritization: Frees up human workers to focus on creative and complex tasks.

Faster Decision-Making: Real-time data processing enables quicker responses.

Better Compliance and Reporting

Regulatory Compliance: Automated systems can be programmed to adhere to specific industry standards and regulations.

Audit Trails: Maintains detailed logs of all operations, making compliance reporting easier.

Data-Driven Insights

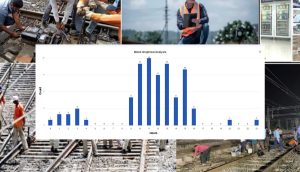

Real-Time Monitoring: Sensors and software provide live data for analysis and decision-making.

Predictive Analytics: Automation tools can forecast trends and detect potential failures, improving planning.

Enhanced Safety

Risk Reduction: Automation can take over hazardous tasks, reducing risks to human workers.

Remote Monitoring: IoT and SCADA systems allow for remote oversight of dangerous operations.

Scalability and Flexibility

Adaptability: Easily modify processes to handle new requirements or increased workloads.

Integration: Modern automation tools integrate seamlessly with existing systems.

Customer Satisfaction

Faster Services: Quicker responses and deliveries improve customer experience.

Consistency: Ensures reliable service delivery, building customer trust.

Long-Term Sustainability

Energy Efficiency: Optimized processes consume less energy and reduce waste.

Eco-Friendly Solutions: Automated systems can comply with environmental standards more effectively.

Delivering Excellence Through Our Core Services

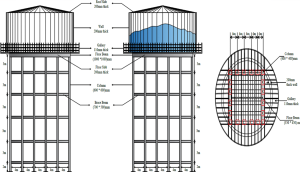

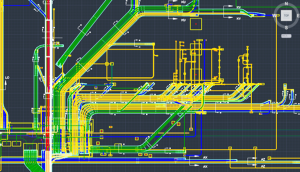

PROCESS INSTRUMENTATION

CONDITION MONITORING

INDUSTRIAL AUTOMATION

ENERGY MANAGEMENT

INDUSTRIAL IOT & WIRELESS

CALIBRATION SERVICES

MACHINE COMMUNICATION